is your vac dropping when you start feeding?

With not much distilling, all the crude would be bunching up and easily splashing.

At 100 micron, you’ll need to be closer to 185-195C and even that may be too low.

Lower vacuum is everything, do you have a turbo molecular pump, a diffusion pump, or atleast a roots blower for your vacuum pump?

Also please describe your devol and terp strip process

It sounds like either you have play in the basket that causes it to sway. I’d check to see if the basket is spinning evenly relative to the condenser and that the basket is level with the evaporator.

You shouldn’t be running the wiper motor that fast the faster the basket turns the faster the crude is pushed down even on a roller

I think you need to show the basket speed down (run it at 50%) and see what happens

You shouldnt get splashing at that speed

Ideally you want 250 rpms max on the basket, anything over that you will get splashing

Bud, can you send us a pic of the unit?

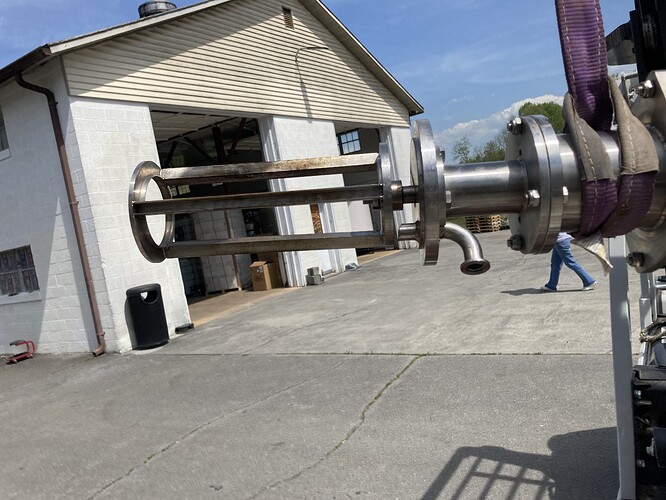

Something is not right here. Can you trust that you are in fact at the temperature that you think you are at? Can you trust the vacuum level that you think you are at? If the answers to both of those questions are YES, it seems like something is fucked with the basket. Has anyone laid eyes on it? If you have a forklift and some straps available, I have found it super easy to strap the motor to the forks, and lift it out to do inspections/sanity checks instead of trying to hold it and remove/install the blades.

bad pic, but you can see how I have it rigged with a recovery strap. Basically slowly pull up with the forklift while you have someone removing the blades so that they DONT FALL DOWN THE CONDENSER TUBE REQUIRING EVEN FUTHER TEARDOWN…(ask me how I know). I hope you don’t have to go that far, but if you do, you can have it off and back on in ~20min or less.

Only other advice I can give with troubleshooting these complicated beasts is constantly change up shit. If I had the hours back that I stared at the thing racking my brain on how to fix vac leaks instead of just fucking around with it and breaking shit, I would have WEEKS of my life back. And rest assured, it is always the dumbest thing that ends up being the problem.

Thank you all for the advice, feedback and suggestions. After a few hours of making adjustments and waiting, I started getting separation. Current parameters are as follows:

Feed: 12.5

Wiper motor: 433

Distillate: 40

Residue: 120

Vac steady at 95 microns

As for if they have diffusion pump, they do but further research needs to be done on my behalf on to rebuild it. I’m still getting still getting some splashing.

So I can’t speak for the gear pump ratios on your system, but on mine, each pump is the exact same. It seems strange that your output pumps are running much higher than the feed pump, and in different proportions than what I would’ve expected. I’ll ask again, what is the condition of the input material? If you rerun your distillate, does some (a lot?) still go to raffinate? When we have reran distillate, virtually none went to raffinate. If you are still getting decent raffinate off of distillate, there’s something fundamentally wrong.

Do you have any more iso K clamps??

Id do 4 symmetrical at minimum and maybe two or more extra on the large diameter flange.

Only for the vacuum issue. The basket issue i have nothing on.

IMO OP should put sight glasses between the outlets and pumps. No sense running the pumps faster than you are producing distillate and your waste stream, doing so just trashes seals and packing faster, and provides more opportunities for vac leaks

I agree. If feed is 12.5, and combined output is 180, either the pumps have differing pumping rates, or something is fucked. Something fundamentally doesn’t seem right…

Very first thing, @Greenbuggy is correct, get some sight glasses before those discharge pumps. You need to be able to see the flow coming off to adjust your discharge speeds accordingly. If you ever are backing up waste, you could be just overflowing your column walls crude collection cup into the disty collection. Doubtful at your discharge rates but it’s a thing. It’ll also is important to see what you are producing as soon as it comes off. You’ll see soooo many things.

Was this system from LM Scientific? I see the “Stout” but that’s definitely looking like an LM. They used the different matte steel instead of the shiny metal of most China wipers.

What is your column jacket temp?

What is your internal condenser temp?

Biggest question: What are running? THC or CBD?

What is your feed pot temp?

What’s your waste (residue) discharge temp ?

Please answer the same and what you just listed for your terp pass, as well as how is the material prepared before ever going into the wiper

Also, what they are saying about Feed Vs discharge speed is your discharge pumps speed added together should be very close to equal to your feed speed as you just splitting the amount of material being pumped

If feed speed is 12 and getting 80% distillate and 20% waste residue, your distillate pump should be very close to 9.6 and waste pump should be 2.4.

9.6+2.4=12. It won’t be exact and the lowest you can typically go is 6-8 on those pumps but it’s a very good guide to how fast you should run the waste and disty pumps. You shouldn’t run them faster than they need to be ran or you’ll wear them out very quickly. Should never be ran nowhere near how fast you are running them ![]() . You’ll gaul the metal and wear down the ptfe shaft seals. You should have replacements for the ptfe shaft seals from the manufacturer and a good local machinist, we literally use @greenbuggy for polishing our gear boxes when they get worn.

. You’ll gaul the metal and wear down the ptfe shaft seals. You should have replacements for the ptfe shaft seals from the manufacturer and a good local machinist, we literally use @greenbuggy for polishing our gear boxes when they get worn. ![]()

Yes the gear boxes are all 4.5:1

Diffusion pumps are literally just oil heaters. You either lost continuity in the heating element, don’t have the right amount or the the right diffusion pump oil or you’re giving the wrong voltage. That’s basically all it can be unless it’s heavily dented internally somehow which is very unlikely unless someone threw (yeeted) it across the room.

DM on my account Instagram and I got you much quicker than can be answered here, haven’t used this site in many many months.

This isn’t correct on a wiper with the blades and rotation the correct directions. Faster wiper speed means more residence time on the wall. It’s very easy to see, slow your wipers down and you immediately start dumping material out the residue discharge.

For OP, this is a Video of a much larger wiper but shows the product we produce (CBD Distillate)

Not to laugh at anyone’s misery but

Where tf are all of the chinese vendors on these threads. They sell and market but when shit goes off its all the american boys troubleshooting the broken poorly made equipment.

@AlphagreenSusan @EchoChan @Yhchem-distillation @YHCHEM_Irene @Terry_Manager

Where are yall at? I know you guys dont sell this model specifically but neither does anyone else on this thread. And realistically yall are closely related - the same way i can ping a vendor and get their attention to issues. But once you got your payment yall dont care.

STOP BUYING CHINESE

DECOUPLE.

This was more of a psa than a rant directed at @mi_organic_gardens, i know youre at a client spot.

Depending on your design it might be the same thing we dealt with. The internal collection basket on ours was not tall enough and crude would come over into our distillate. We welded a bigger cup on ours and works awesome now

@NewLevelProcess Thats just a bad take.

Yes there’s issues with Chinese equipment, but there’s just as much issues with American equipment.

It looks like this was purchased through an American distributor, Stout surely doesn’t sound Chinese to me.

It’s good to use an American distributor of Chinese equipment to help interface with them when there’s warranty or troubleshooting issues. However, when your US side distributor leaves you hanging and you don’t know who even made your wiper, what are you to do.

That’s not saying some Chinese companies don’t just suck majorly; like LNeya, but so do many US companies.

Its not a take its experience.

Ive unboxed and setup just under a dozen wipers now. All with US and EU support. I have never once come to the fourms with my issues on getting things up and running.

The worst expeirence i had with a brand new UL listed CTS was a blown drive. Which was promptly overnighted without any bellyaching or excuses.

On the opposite spectrum of experiences - i was called in to help get a china wiper running and after three months of arguing and a few threats of chargebacks they finally came over to simply lay blame on me for setting it up wrong. The kicker is - i didnt set it up.

Idk what your take is but i like equipment that is safe for me, the products i make and has support.

Heres a video of that good quality chinese engineering -

Closed stopcock still pulling

@NewLevelProcess I have also never come here looking for help on the many Chinese wipers I’ve used and have always got them running.

CTS is a great company, there’s no question but very pricey for the output rate.

I agree, some companies suck, but they equally suck everywhere.

HVE wipers are US made and are straight trash.