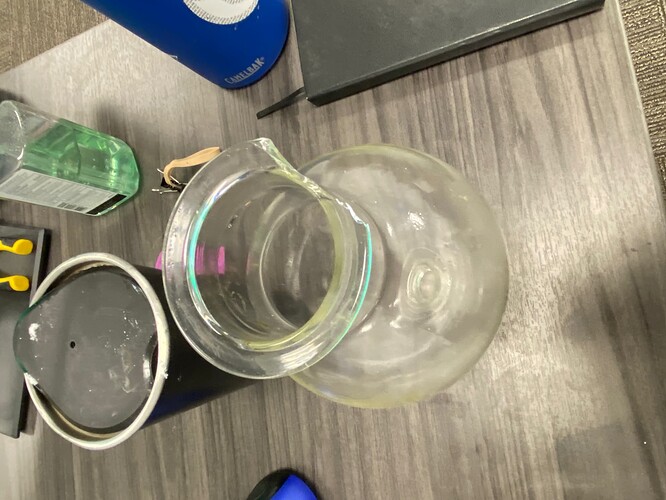

Looking for the name of this piece if anyone knows, it’s a glass globe that the crude passes through before entering the wiped film.

that’s an interesting piece, what brand/model of wiped film does that come from?

can you share a closer photo of the bottom joint? do you happen to know what type of connection that is (bottom or top)? bottom kind of looks like a KF flange

also, is there anything that attaches to the top or is that just open so you can pour crude into it?

Hopper

it’s a kf joint. Also it’s a generic chinese unit - branded “Boston Distillery” on one piece of stainless but there is only a traditional glass short path for sale at BVV with that branding.

There is a lid, the crude comes in from a pump.

might just be custom… i’d think it could be called a bump trap if it weren’t for the size of the one connection.

Doesn’t look like it would be too difficult to repair if it’s just that one flange cracked

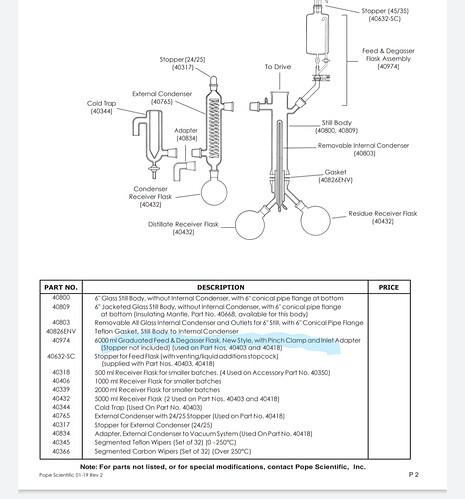

I got that from this parts list

I have no idea about any of this, just did some googling

That would make sense based on the function, but no hits finding a replacement. Probably just need a glassblower to fix the damn thing.

absolutely, plenty of lab glass fab/repair companies that could handle that. I like Chittenden & Adams, they always nail the thing

if it were me I’d look towards finding/fabbing a stainless vessel to meet both those connections, IF that’s possible, and if you’re ok with not seeing inside (that can be remedied with a few inline sightglasses). even if it costs more than one glass repair/replacement, if a glass piece breaks or chips once there’s a good chance it’ll happen again so you’ll often be better off in the long run

It’s helpful to be glass, because you can see the inlet feed. We are always getting clogs in the feed line and have to hit it with a heat gun when it clogs.

Hit up @goldleaf_scientific for any repair work or customizations, bet he can make one of these super easy

do you use any kind of heat wrap around the feed line? we used to have the same issue, using those has saved us from having to heat gun pretty much ever

We have heat wrap, but not enough to cover 100% of the inlet line. We have a recirc heater on a jacketed input tank as well.

If @PRSPCT is still around here, they may be able to put you in touch with the oem.

iirc they worked with Boston Distillery on their wfe and 72l spd

That can Easley fixed by your average glass blower

O please would love to see this spd any links ?