So I’m pretty sure these are terps condensing on the cold aluminum sides and lid, but I would like someone to confirm or deny.

I winterize bho with etho, I pour the etho onto a ptfe sheet inside my 5g vacuum chamber. I heat chamber to 100c until liquid etho has evaporated, until oil is thick and semi stable. I then pull vac for a few hours @ 120c. Then I up the heat to 160c to decarb under vac. The oil temp is lower then what I set the vac oven, it loses several degrees from the aluminum and thick ptfe sheet, probably 10’f. This has been the routine the last several runs. I read decarbing under vac helps reduce oxidation and helps retain color, which is important since I don’t crc. It seems to work well, I can decarb and it doesn’t darken very much. Also I do not have a cold trap.

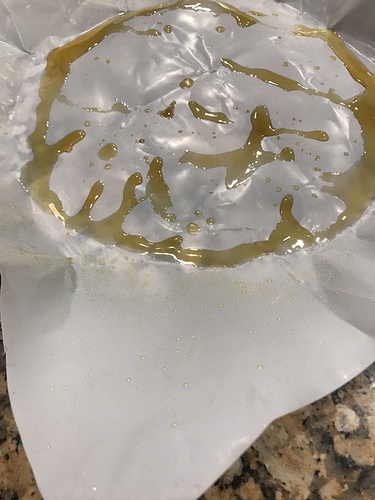

My chamber is convex so oil will settle around the outer ring until I tilt and run it across the sheet. The first time I decarbed under vac with some really sugary bho, liquid condensed on the lid and dropped back onto the middle of the ptfe sheet. I didn’t know what it was, it was in the middle of the ptfe by itself since the oil settles on the side, so I would open the chamber and clean it up with an alcohol paper towel. I was worried it was glycerine leaking from my hg gauge, so I removed it.

Did the same procedure with sugary bho, happened again. I continued to clean up the drops if they landed on the ptfe, because it looks like the terps are eating my polycarbonate lid. I don’t want to smoke poly laden terps.

I’m guessing terps are volatilizing and condensing on the aluminum sides and metal valve.

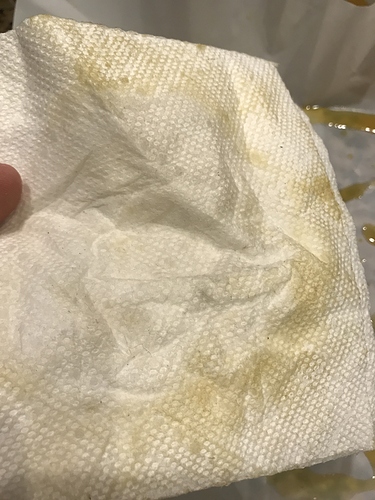

Since then I tape a paper towel under the valve, since that’s the only place it will condense enough to drip. I have a stainless steel chamber with a glass lid on order, so that should resolve my concerns about leaching poly into my oil. The terps have eaten away and created cracks around the valve.

I just got a batch of really grassy smelling bho. It was soft and mailable at room temp. Did my normal procedure and it condensed like crazy. Far more then any other oil I’ve run. I might have decarbed this oil too hot? Sugar bho needs higher temps to decarb, but this stuff wasn’t sugary.

Here’s pics of the last run. It’s a crazy amount of condensation, especially considering this was only a 16g sample run, and the previous runs were ~100g of sugary bho. I was blown away, I could literally watch it collect on the sides and lid. Idk if it’s just super terpy trim bho, which would explain the grassy smell, or maybe I was just decarbing too hot, vaporizing some of the oil which condensed on the cold sides