I’ve got a 10 HP CME hammer mill. I’ve ground 10’s of thousands of pounds in this mill with no problems. The latest batch of CBD Hemp I’m trying to process is clogging the screen with sticky hashy residue. Anyone have tips or tricks on what to do here? The hemp looks freaking beautiful, smells amazing.

How many pounds are you getting thru before your screens are clogged, & how much more do you have to shred?

If you can, blending it with a dryer & less sticky material can help, but I know thats not always an option. I’ve always wondered about if there is a paint or non-stick coating you could apply to the hammer mill screen to reduce stickage

Sad to hear that you went with a CME, but @KannaMill can shed some light as to why you are likely clogging the mill.

First, does the mill come with air assist? Any dust collection being used? This helps move the material through the mill.

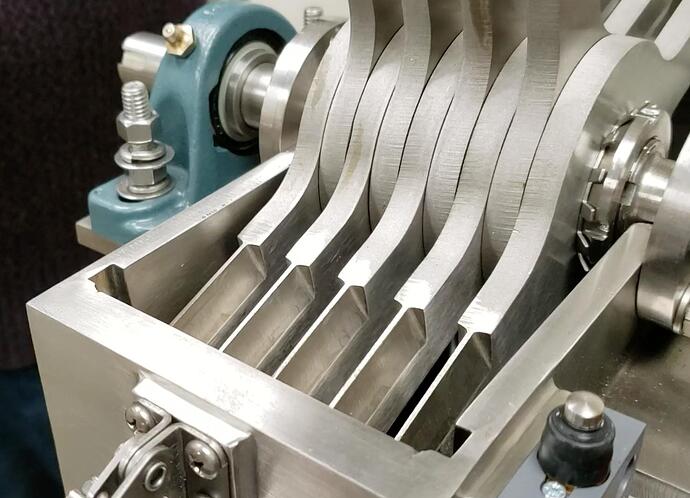

Second, what do the Hammers look like? Are they blunt hammers? Are they worn out?

Third, how are you feeding the mill? Dumping? Metering?

Fourth, what screen size are you using?

Fifth, and possibly most important, what is the moisture content of the material? The higher the moisture content, the larger the output size. Think of mowing wet grass with a lawnmower, stuff will stick to everything inside the mill including the screens!

Happy to talk some more…

-Dan

I have heavy duty air assist and dust collection. I just cleaned out all my filters and it helped a tiny bit.

They are blunt hammers and they look almost new. A couple dings.

We hand feed the mill.

We are using 1/2" screen currently. 3/8" clogged super fast. I have a 3/4" but we’ve never used it.

The moisture content is actually very low. It’s just super sticky.

Try freezing it with some C02, or LN2? Might help with the stickiness…

LN2 does work well. It makes the material very brittle…see below video for reference.

LN2 Test - KannaMill

My old company had a 10hp CME mill… LN2 was very effective when dealing with sticky hemp.

I’ve got LN2 dewars setup for gas use. I guess I could get them setup for liquid and just pump into the mill. What rate of liquid would I use?

I am not sure feeding liquid LN2 into the mill would be ideal, but rather use it to freeze material before the mill. In that case, you may only have to use very little in order to freeze thoroughly. I can’t speak as to how the CME mill would react to LN2 but our KannaMill’s handle it well.

Freeze it first and then feed the mill

Freezing it first would obviously be the best method. But I can’t afford to rent a refer truck or buy a walk-in. A chest freezer would be slow, but I guess it would be possible.

Yust mix dry ice treu the biomass at 3 biomass to 1 dry ice give it an hour to freeze up then run it treu the mill with dry ice and all

Hi, what is the moisture content on the material? What size screen are you running? What are ambient temps like, what bout discharge temp of the material?

I’ve had this issue with the CME mill before. Found no solution. Clogs to quick to have a hot swap procedure.

I keep telling them its only going to get worse as quality goes up. Better find a solution quick.

Look in to the blue hippo. Best grinder I have come across. 1000 lbs a hour no problem. Have pushed it to 3k per hour, but it was a major dust storm. Couldn’t see shit.

I’ve used hippos as well. They’re workhorses for sure. Best thing you can do with that is add big dust collection system and a VFD to the mill if it didn’t come with one. Its really dangerous being covered in combustible dust btw. OSHA 's not a fan. Gotta engineer it out of the picture.

No dust at 1k an hour with our collection system. It’s when you push it it turns in to a huge black out weed storm