So sometimes I have an idea, and actually have the time and resources to bring it to fruition.

I make my own personal carts, and some for medical folks. I want to be able to decarb with heat, while maintaining my terpenes…if possible.

I’ve made a pressure vessel, with a teflon liner to do the job. 3" triclamp, 2.650 ID, for a little added wall thickness. The teflon liner will eliminate transfer loss, and will make dealing with the decarbed oil a little easier. One PRV for good measure. Two 1/4" valves, one for vacuum and one for nitrogen. My intention is to put oil in the teflon cup, assemble the little rig. Vacuum out atmosphere. Fill with nitrogen. Vacuum and purge with nitrogen again…maybe…for good measure. my intent is to remove all oxygen. I will pressurize the vessel with nitrogen, maybe to 30 or 40 psi.

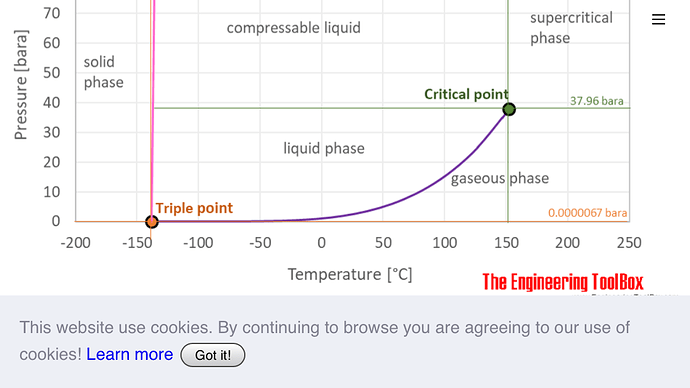

At this point, there should be minimal oxygen in there, and some added pressure to keep terpenes from turning to vapor with the heat applied. Is vapor pressure the proper term there?

So now, with my desired conditions within the vessel, I will put it in an oven to decarb at 240 degrees Fahrenheit…or there abouts.

I was going to add a compound gauge, but they cannot live in a 240 degree Fahrenheit environment. I left the center location on the lid open to have the option of adding another port, which would be piped outside the oven to the compound gauge to monitor pressure. I imagine, with a little forethought and application of basic logic, I wouldn’t exceed 100psi in there after adding my nitrogen pressure. My thought is to leave at least 60-70% of the teflon cup volume empty for head space.

I know @cyclopath has done some decarbing under pressure as has @FicklePickle. My hope is to play with it a bit to see if I can yield anything of value SOP wise, but I move slowly.

I just want the tastiest hydrocarbon extract in my carts…since they are for me…

If you see a flaw, aside from the brass 1/4" pipe nipples, or offer critique on design or process…please blast away. I’m just a machinist who likes cannabis…