I’m running a USA Lab 10L SPD (china glass) with their 21CFM pump. I’ve had numerous runs with this rig and it’s unbearablely slow. I broke it all down and cleaned and regreased everything and got down to 40 microns loaded. It’s still running dawg slow. By slow I mean 1 liter per 4hrs or so. I spent last night trying to wrap my head around this but I’d figured I’d ask fo input…any input would be appreciated.

What size SPD head are you using on the 10L rig?

That sounds like the throughput of a 24/40 head. You may want to look into getting a new RBF with a 45/50 joint (or larger) and a 45/50 SPD head.

At 21cfm, that pump may be a little undersized for a 10L, but if you’re able to pull down to 40 microns on a system that size, you really should be seeing more than 250ml per hour.

You said it pumped down to 40 microns, is that roughly where the vac level stayed during distillation or did it spike much higher during your run? What are your temps and stir speeds?

The head joint that fits the BF is 34/45. And the output is 24/40. The vac stayed between 40 - 80 microns the entire time. BF temp was set to 205 and stir was 750-850.

What’s your head temp?

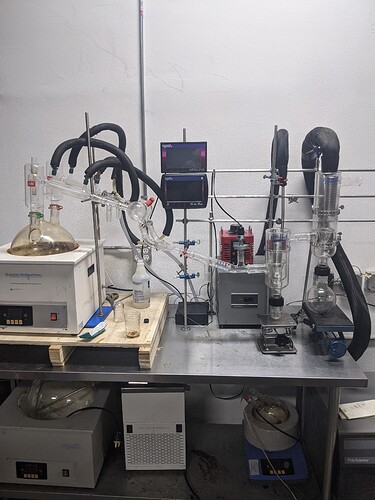

Post a pic of the spd and current vacuum setup.

True most 10/12 liter setups like dual Edwards 30 style pumps.

That’s a 2liter outdated head on a setup not made for that.

That’s how it was sold to me unfortunately

Was about 170-180

Stop what you are doing and give my shop a call. Well help save the day.

2 edwards pumps?

Your flask also shouldn’t be coated black while running.

That was just from pumping it down and getting rid of the muffin. It had settled down but the walls were coated as you can see.

Muffin is due to not fully decarbing

This is basically a blue print of a proper 12 liter design. If you strip it down what’s important is the pump connections/pump array as well as the dual traps setup. This is what you should be aiming for

And all seriousness you should throw that combination of glass away if you want to succeed.

Well throwing it away isn’t really an option right now. Would I be wasting time with a dif pump?

Yes, you need to solve your other issues first. #1 Wider bore head, #2 cold traps/ volatile management, #3 addition of a roughing pump and another mains pump.