Ladies and Getleman,

So first, sorry for my unperfect Engish, I’m french native ^^

What about this topic : We are working on distillation since two years now on very small batches (Yes seriously our receiving flasks on SPD are 100ml, thank you french gouvernment …). Even if we do small batches, we try to respect all the process since the beginning because we work with passion.

We are starting to scale a laboratory in Switzerland and will be more than happy to have your review about it.

The steps : we follow the steps of Hemp Processing Equipment Selection Guide v2 found on FUTURE4200 forum.

We also follow the SOP’S of Good Life Gang and our own SOP’S we are writing.

This setup is design to extract at least 50KG (More or less 100Lbs) of CBD Biomass per day.

Step 1 : Extraction

We would love to work with Delta Separation CUP15 but unfortunantly they can’t deliver us in EU. So we decide to go on our best manufacturer friend Ali (Little name for Alibaba).

We find something who’s really look like to CUP15 who’s finally (stop me if I’m wrong) a big washing machine.

Not a lot of detail on it but the specifications are the following one :

- Diameter: 600mm

- Volume: 40l

- Limit load: 50kg

- Speed: 1500rpm

- G-force: 756

- Motor power: 3kw

- Weight: 800kg

- Overall dimension(L × W × H): 1300mm × 880mm × 900mm

- MOC:SS304

Including Base unit, Ex proof motor, Viton Seals,Touch screen panel with PLC

program,Inverter control box, Closed type filter bags, Tri clamp

fittings for feed and drain port, a set of spare parts.

It seems you can cold the solvant on this machine but I’m not really convicted about is capacity. We will chilled Ethanol before at -50C on freezers. Do we have to do the same for Biomass ?

Step 2 : Winterisation

When we drain from the washing machine we put on 20-25 liters jerrican and store in -50°C freezer for at least 4hours.

Step 3 : Filtration

We pour our cold winterize ethanol on a 20L buchner. Basically use paper filters (From 50 to 3 microns). We are thinking to use pouder filter espacilly for chloropyl remidies and pesticide but we have to read more about this subject.

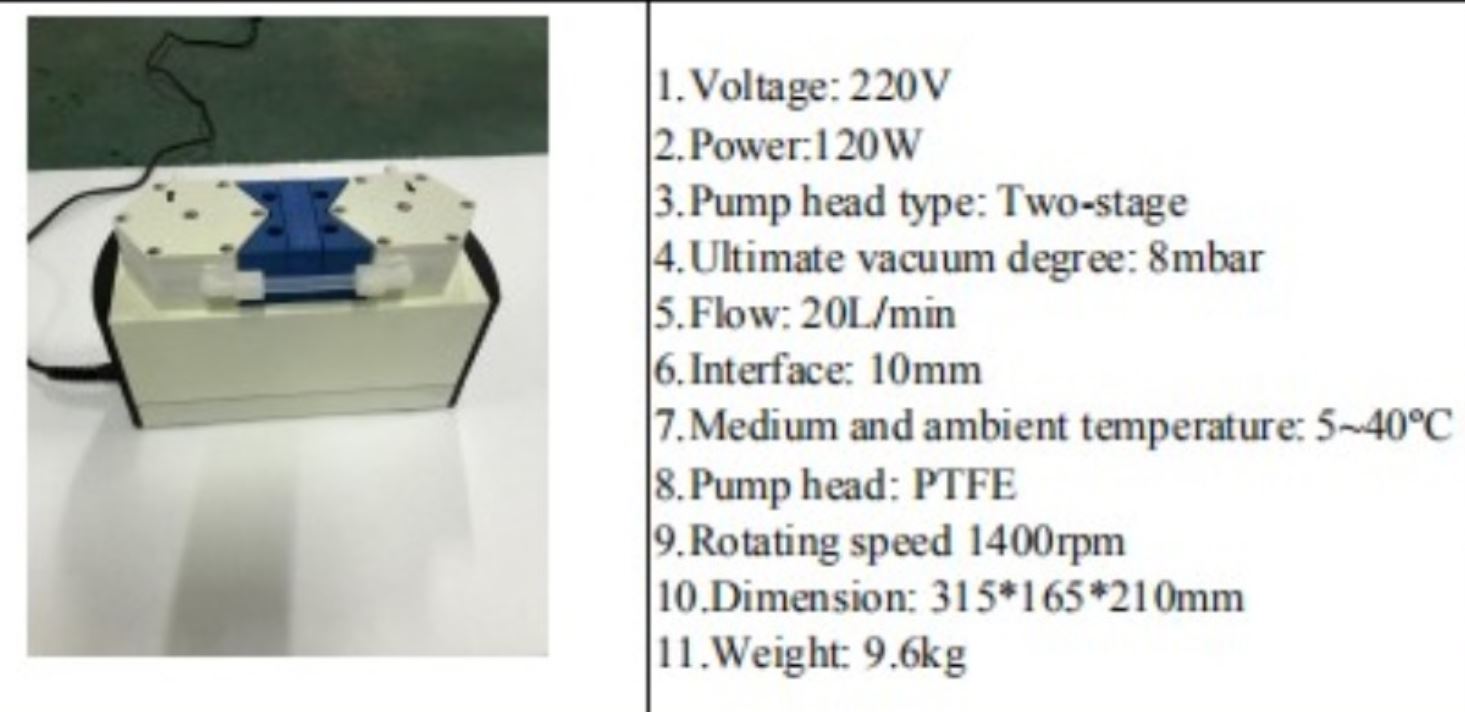

With this buchner come an Oil-less pump.

Step 4 : Rotary Evaporator

We now put the solution on the rotary evaporator. We choose a 50Lwho look like this one :

I’ve just modify the vacuum pump for the same as the one at Step 3. These pump without oil looks better. They don’t have a deep vacuum as the oil one but they do the job.

Chiller is 50L and goes to -30°C

Step 5 : Decarb

We will do it on big “cooking pot” on heating plates with stirring. Will find it on my distributor of small laboratory products in France I supposed.

Step 6 : Distillation

Here come the big boy ![]() SPD 20L Who will look like more or less to the one of AI :

SPD 20L Who will look like more or less to the one of AI :

As soon as the lab turn at 80% the objective is to change it for a WFE but we currently don’t know how it’s really work so we go on what we know first.

ATM, we choose a 8L/s double stage vacuum pump and a little Chiller for condensers.

Step 7 : Cristalisation

We are thinking to take a Filter Reactor from turnkeylabsystems who looks very nice. Not a lot of infos about it at this time because we know how to cristalize THC not CBD !

But after few research it seems we can acheived it easily by mixing CBD distilate with Penthane and chill to 0°C … Anyway I think process will come with the filter reactor.

Step 8 : THC extract

This point we don’t really know what to do with. I’ve seen HPLC systems but currently don’t know how it’s work.

Does it possible to isolate all the cannabinoids with this type of machine ? I don’t know but if yes, I will for sure take a look on it later. During the firsts months we will only store this mother liquor on our freezers.

So, now, big question : What you think about this setup ? Does it make the job or I’ve some red flag on it ?

Before the end of this message I (we because we are 2 on this project), would like to thank you all for this unvaluable sharing of knowledge. Knowledge is better than gold.

Have a nice day.

@The_Plant_Pamper