Neem oil and similar things affect the boiling point untill they all boil out. Next time switch from diaphragm to sogevac style pump and rio the vapors out.

I’d be slightly terrified to run the sogevac on my 50L… like I’ve got a 65 bi fc… but 42cfm worries me. That being said it worries me because I’ve never hooked up something that heavy to a roto

@anon42519203, if it’s contaminated with oil, will it pull out if I run it on the wiper?

Are you sure you don’t mean 150F? Your roto looks like it has water in it

Lol yes I entirely mean 150C

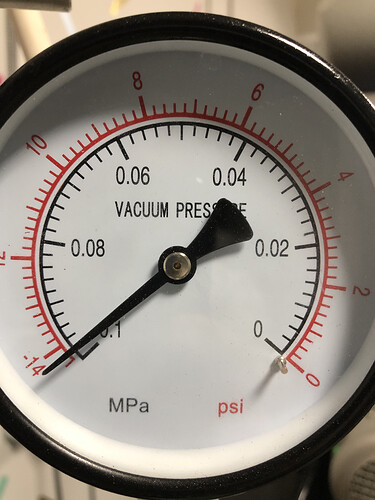

Okay, so you’re at 150C and what vac level?

At 150C and fairly weak vacuum you’ll probably bubble for hours and hours while the fraction you’re bubbling comes out.

Between 60C and 150C under deep enough vacuum the volatiles come out quickly but the fractions are much slower or won’t come out at all if your vacuum level isn’t very low. Could that be what’s happening here?

If the still is inefficient you could also end up with the fraction dripping back into the flask. That can happen when the vac level is too high. When the bubbling vapors hit cold glass the bubbling fraction will condense faster than the vac can evacuate it

This may be exactly it

I wouldnt recommend thay for a roto, it will piss off the pump unnecessarily. If youre needing speed on a roto and not already spitting solvent out of your diapragm, its a heating issue. I added a coil in my bath and cook to 155C with an 8 head vacubrand.

I also use a savant cold trap after my roto to stop everything i can. My roto runs somewhere around 10-15gal/hr of ethanol with an enterence temp of -20C.

The coil i made was a 1/4” stainless tube ended in a couple swage barb fittings. SINGLE LOOP with only a bit of overlap. It terminates and goes 90 up where the neck of the roto ball sits. Ill post a picture. Then a hose is connected to each side. And i throttle it using the inlet stopcock on the roto. Basically spray vaps into the roto ball. You want only a single loop because otherwise you get cavitation and back flow if its not fast enough which becomes annoying.

The summit roto comes standard with that setup.

Fyi, with 25L of material in a 50L at 155C even when the coil stops dripping theres still probably 200ml of solvent in it at least. Pesticide bubbles isnt a thing but if youre working on crude its probably the terp and heads fraction trying to get out.

That’s just cfm at open ballast. It has like 1/20th that at vacuum.

Wet brah

Youll never need a soge on a roto. I honestly turn off my roto and just keep it in a zone until the end and still get 10-15Gal/hr.

Fastest with heptane… its godly.

Temp is everything on a roto. Hot and fast. I use 120-130C for heptane because it cant handle 155C until i fully purge it.

Also, make sure your dip tube leads pretty far into the boiling flask or you end up with alot of flashing and bumping in the first chamber.

Wow that much entering a -20c ![]()

I’m also positive someone probably had the barrels sitting near the oil bath and it got spit into… 99% sure this is oil

There are volatile oils that separate from crude in a short path at 80-120C under deep vacuum and only need to travel like 10 inches out of the mixture before they start to condense against the glass. No chilling needed.

You can fix the problem to a degree with deeper vacuum. When volatiles come out more quickly the system temperature also goes up and they should exit the flask with less problems.

I don’t know if a roto is small enough to remove all of the volatiles from a mixture like this. I’d probably still rely on a quick devol step in a short path or wiped film.

Oh wait, i thought we were just talking about running rotos hot.

Its -20 before the coil, a bit warm after. So it enters the system probably at 90-100F.

Ahh yeah so you etoh runs though that coil. I usually run mine at 90 until the etoh is almost boiled off then I ramp it up to 150 and devol/decarb at the same time. But now I have a load mixed with dirty oil… think I can pull it out on the wiper? @BreakingDabs