For sale, $8K, currently located in Seattle, Washington.

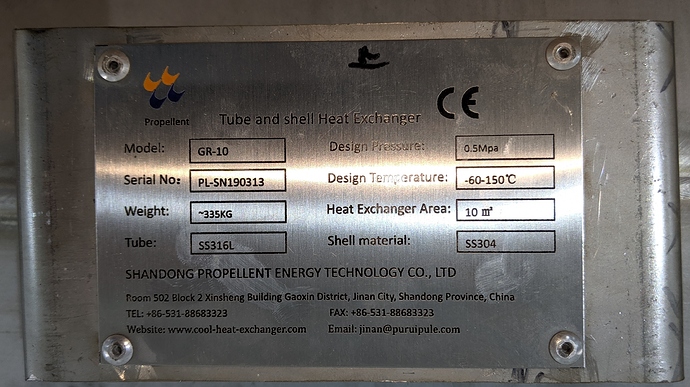

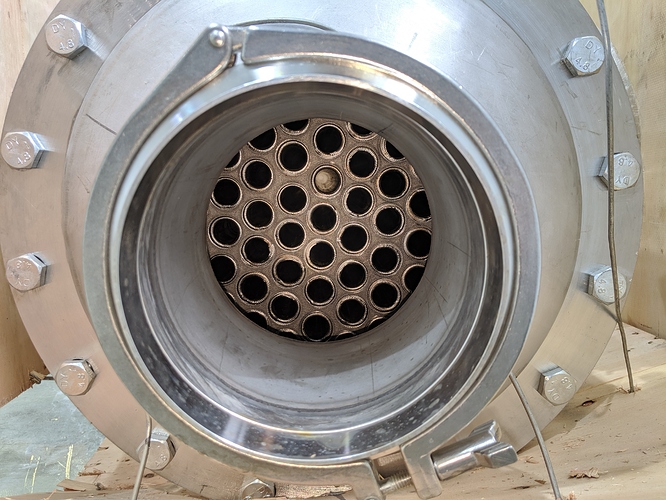

Tubes are 316SS, shell is 304SS

Unused, Buyer pays shipping, project changed course so it is not needed.

Based on my first hand inspection the welds and construction looks good, would be very useful for a large falling film.

0.75 MPa Rating

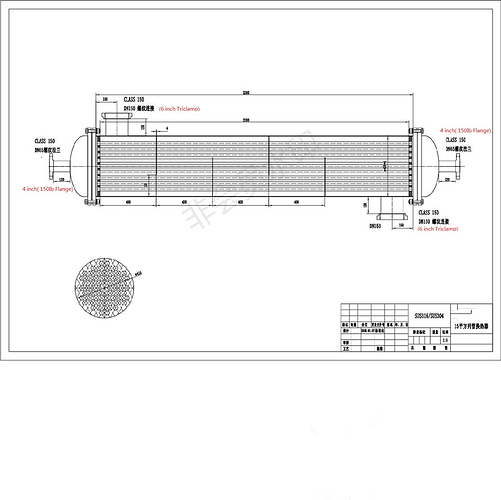

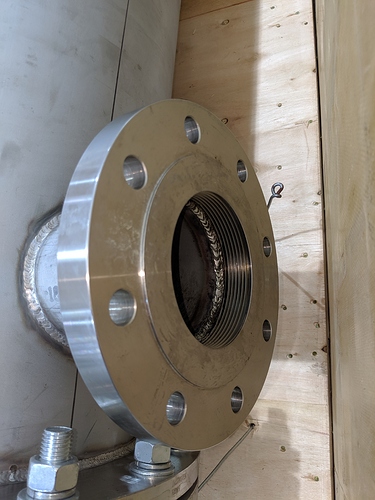

4" Flange(for coolant) & 6" Triclamp Connections (for process fluid)

Purchased from cool-heat-exchanger.com

Drawing of similar GR-15 model attached.

1 Like

I sure don’t need this, but I really want it.

6 Likes

Why did you acquire this, and why did you not end up using it? Very curious

1 Like

acquired it as a sample to asses quality of Chinese heat EX from this vendor, to build a falling film evaporator for ethanol.

Client changed course in the middle of the project, opted to use a different domestic source and to change the size of the project, (not due to any obvious faults with the Chinese heat EX of which their are none)

Extrapolating based on the BZB FFE which has a ~2 m^2 surface area and does 100 Liters/Hr this unit should be able to do around 500 Liters/Hr of ethanol evaporation or cooling.

Using the same rough scaling the BZB uses 10 tons of heating/cooling last I checked which would put this unit in the 50 ton range…

Found the exact drawing:GR-10_Sample_Drawing.pdf (221.3 KB)

I have a DXF of the drawing if anyone wants that.

interesting unit. with an efficient design something like this could push well beyond 1000lph easy.

2 Likes

potentially, depending on the temperature difference(Delta-T).

The BZB has been pushed to close to 200L/hr I believe, and my personal opinion is that the bottleneck in their system is not the m2 of evaporation area - with a differently configured system one should be able to get a fair bit than that out of it.

I’d happily throw 1000L/hr at this one. Probably a lot more.

good point, my estimates are conservative.