- Feeding pot

- Magnetic coupling drives stirring

- Jacketed evaporator(with condenser inside)

- condenser

- Circulating heater(work with jacketed evaporator)

- Heating and cooling circulator (work with internal condenser)

- Controlling system(show vacuum degree, control and display 2.rotary speed)

- Distillate Receiving bottle(low boiling point)

- Residue Receiving bottle(high boiling point)

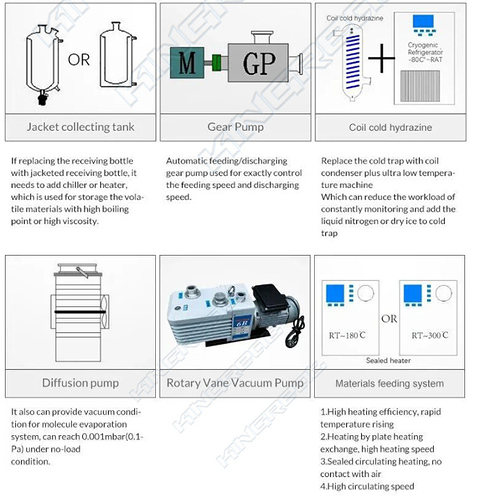

- Rotary vane vacuum pump

- Diffusion pump

1,Evaporation efficiency is very high, can reduce retention time, with minimal time delay.

2,Molecular distillation system is composed of high borosilicate glass 3.3, 316L stainless steel and PTFE, so it has excellent anti-corrosion ability.

- The main part of the molecular distillation system is made of high borosilicate glass 3.3, and the whole operation process can be well observed.

4.The high precision distillation cylinder body enables the liquid to form a complete integrated film on the heating surface.The inner wall of the barrel body is smooth and bright, not easy to stick to the material and scaling.

5.imported brand variable frequency speed reduction motor,safe and reliable in operation;equipped with self-cooling fan,it can continuous working for a long time.

6.the magnetic drive system makes it possible to seal the whole machine.the transfer bar of the drive motor does not need to pass through the main distiller.the whole set of the distillation system possess good sealability.The min vacuum pressure can reach 0.001mba.

7.the max temperature of the equipment can up to 250ºC/300ºC ,accurate temperature control can achieved.

8.maximum the theroretical vacuum degree can up to 0.05 mbar or 0.001mbar.(secondary diffusion pump is needed)

9.You can free choose of scraper film forming system and self-cleaning roller system.

Clamp feeding tank Magnetic coupling driving agitation

clamp evaporator(containing condenser) dry ice cold trap

high temperature thermostats(equipped with clamp evaporator) heating and cooling circulator(equipped with in-built condenser)

control system(display vacuum degree and rotor speed and control rotor speed) Light component receiving bottle(high boiling point)

`high component receiving bottle(low boiling point)