lmfao bound like shibari ahahahahahha. I cant talk to almost anyone rn tbh… ![]() I keep getting yelled at for talking about my work ahahahah

I keep getting yelled at for talking about my work ahahahah

I cant say more, but its easily doable.

no such bindings on me lol

I will believe it when I see a TLC plate with these two seperated with reported rf values. If you can seperate these isomers via chromo you should be working pharma as a phd researcher.

Maybe I am(or will be…). Follow my Insta ![]() … Anyways… TLC is not always conclusive.

… Anyways… TLC is not always conclusive.

I can easily separate your cannabinoids for you, you just need the $100-500k for machinery and my training/consult costs…

I can even bring my PhD and process/analytical chemist from a reputable separation science enterprise, to assist, for an extra fee if you would like…

This is being done as we speak, deny it all you want lol.

Also, don’t the two isomers have fairly different vapor pressures, thus possible to isolate via fractional distillation, like in a spinning band still?

Never seen their boiling points reliably reported, i cannot imagine these being terribly different and would be rather tough. Seperation via the patent is done with a trefoil cel1&2, these are upc columns that seperate milligrams at a time. Not practical for industry but great find my man!

Unfortunate this thread has quieted down. Chromatography is probably the only tech currently available that can seperate THC (8,9, whatever) from CBD. Boiling points, if they can be believed, overlap. Delta 8 is lower than CBD, Delta 9 higher. That would make for tricky work on a WFE. There is a process currently under patent applied for that is seperating all 3 with column chromatography. An HPLC unit does this every time we run assay on product, so, it works. It simply a scaling issue.

Hey there boss, I was curious if you had a good standard for supercritical runs for processing distillate? Looking for good temp/time/pressure ratio.

First off what system are you running?

A good base setting to start with is

3000psi

55C internal temp

125 gr/min

4-6 hrs run time

See how that turns out and then you can start playing around based on your desired results.

we are at 2800psi and 52C for CBD with ok results.

our products are still in R&D… they’re not ready for market.

should have new labs for everything sometime soon.

started with dried cured flowers from the October harvest.

bagged and binned each separately by strain. stored proper.

blended the material for 20-30 seconds on low.

dry sifted thru 120 micron screens at room temp.

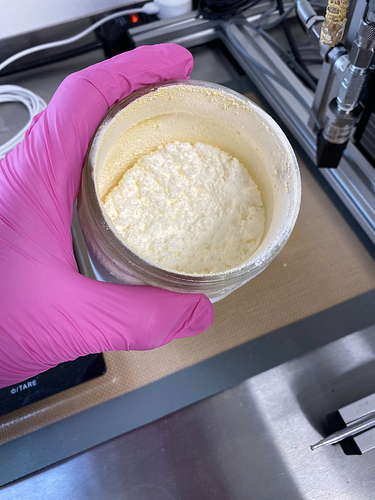

we are pulling this straight from the extraction vessel – no post work.

cold:

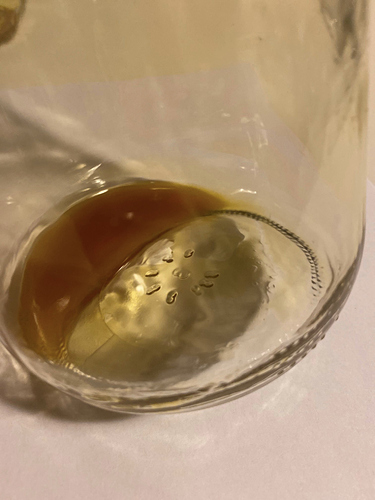

warm:

raw/unfiltered:

love the look and feel, but taste is too ‘hempy’… no terps = no go.

not yet proficient in extracting terpenes on our small system.

not sure if it’s physically possible yet, either. will test and report.

we are also exploring ethanol as a co-solvent during extractions…

I’ve found very little research on the subject, but some articles show promise:

https://pubs.acs.org/doi/pdf/10.1021/jf980982f

http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.590.8046&rep=rep1&type=pdf

https://pubs.acs.org/doi/abs/10.1021/ie000224q

https://pubs.acs.org/doi/pdf/10.1021/ie00038a033

https://pubs.acs.org/doi/abs/10.1021/ie990015+

any help or insight would be accepted and appreciated.

thanks for your time and attention. much love!

If you want terps you’ll have to extract without decarbing first, also, ethanol will wreck the terps unless you pull them before introducing ethanol.

Cosolvents with CO2 can drastically alter what you’re pulling and what parameters are required to get your desirables. Multiple collection vessels are the key to getting good fractions.

I agree with this 100%

My best results on the SFE have been with bone dry and finely ground plant material that has not been decarboxylated.

I had tried many different parameters to extract terpene fractions – subcritical, supercritical and otherwise – with limited success until I did some thinking and experimenting with collection pressures and densities. I now am achieving some of the best and most consistent terpene fractions that I’ve gotten to date inline with my typical supercritical extraction runs.

When I was running the Waters I had trouble getting it down to subcritical and having it perform well. If I remember correctly it had to do with the pump being a liquid co2 pump and me starting with gaseous co2. Got pretty damn good results with supercritical but the thca would clog everything and made pulling the yield a bittttt sketchy with random blockages and all lol

wish I had a machine behind a blast shield in the middle of no where so I could try pentane as a co-solvent…

At this point what would be the advantage over a closed loop butane setup?

Selectivity is the primary factor behind cosolvent usage. You could do inline chromatography that would require different energy inputs to get the desired speed and efficiency while leaving behind unwanted components.

I’m of the opinion that if engineered correctly, CO2 with the appropriate cosolvent could allow for more efficient energy usage. Potentially, using significantly less non polar solvents and electricity.

That is certainly an interesting concept. Seems to me throughput would drop and adding a stationary phase would offset efficiency savings with the cost of media. I could be off the mark, but I just dont see the viability of CO2 extraction in the future. I run an SFE daily as well as all downstream processing and product formulation and honestly can’t wait to just run a closed loop.

I’m a week or so out from running an ETS MEP30, haha. I know the feels.

I’d like to get some help on thc seperation on the Waters SFE.